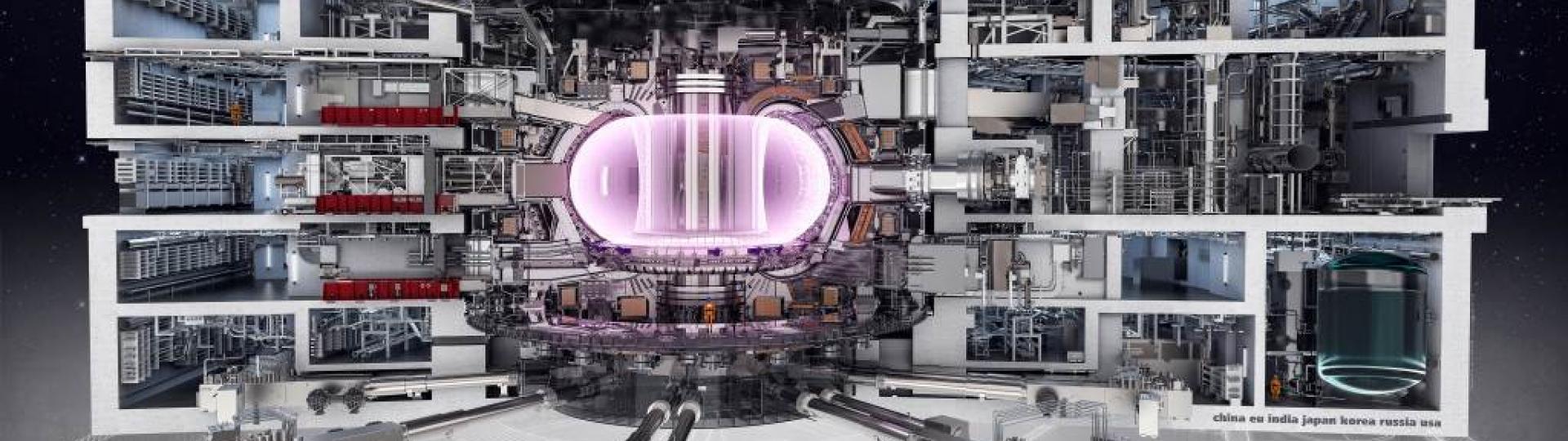

Today, 35 years later, 35 countries from all over the world are jointly building the ITER reactor, the largest fusion device in the world. Constructed in the south of France, the Tokamak (Russian: toroidalnaja kamiera s magnitnymi katuszkami) ITER is a project whose main goal is to achieve a 10-fold energy gain and thus demonstrate that it is possible to use controlled thermonuclear fusion to produce energy on a massive scale. In addition, it will be the first fusion device to test the materials, technologies, methods of plasma diagnostics and control needed to build future commercial power generation facilities.

Thousands of scientists and engineers from around the world face many challenges, including:

- development of construction materials resistant to huge plasma temperatures (150 million Kelvin degrees) and bombarding with streams of high-energy particles,

- precise assembly of several-metre-long, multi-tone elements with millimetre accuracy,

- development of electronic and IT systems tolerating significant ionizing radiation, large neutron fluxes and magnetic field,

- new methods of plasma control in order to achieve discharges lasting even several minutes.

In 2010 the ITER project was joined by scientists from the Department of Microelectronics and Computer Science (KMiTI) headed by Professor Andrzej Napieralski. Our research team conducts research in the field of design and implementation of complex electronic and information systems (Instrumentation and Control - I&C) for the purpose of collecting, processing and analyzing data coming from ITER tokamak diagnostic systems.

The cooperation on this project is a follow-up of previous work carried out at KMiTI for high energy physics experiments, including FLASH and EXFEL gas pedals at DESY in Hamburg. Many years of experience in the construction of modular, multi-channel electronic and IT systems enabling data collection and processing for particle gas pedals control proved to be very useful for Tokamak diagnostic systems.

Within the framework of the ITER project, TUL scientists are involved in developing the methodology for the design and integration of complex diagnostic systems. It should be emphasized that particular elements and systems of ITER Tokamak will be designed and manufactured in several dozen countries involved in its construction. From the beginning, the electronic and information systems must be designed in such a way that they can cooperate with each other and be easily connected and integrated with the machine.

We have developed and built several prototype demonstration systems and used the above mentioned methodologies in practice - from design through implementation and testing to integration with the central control system and other tokamak subsystems. Our experience and skills gained so far, confirmed over a decade of cooperation with ITER, have been highly appreciated and since 2019 we have been included in the design of target I&C systems (including a system for monitoring electrons emitted in plasma) to be installed in the device as part of plasma diagnostics.

Plasma diagnostics is an essential part of the ITER Tokamak, which aims to study the properties of the plasma, its behaviour, accompanying physical phenomena, as well as new technologies and materials. The conducted scientific research will improve the process of production and long-term maintenance of the plasma. In addition, during the operation of the tokamak, information from diagnostic devices is used to protect and control other elements of the whole. Diagnostic systems must work properly in extremely difficult conditions in the tokamak chamber and its environment (e.g. high temperature, strong magnetic field, radiation) and must not disturb the processes taking place in the tokamak. We distinguish between two types of diagnostics: active and passive. The first one consists in observing the result of interaction with the plasma (e.g. by measuring and analyzing the wavelengths recorded after a particle stream is fired into the plasma). The second one involves continuous observation of the effects of phenomena occurring in the plasma (e.g. by measuring wavelengths of radiation emitted by hot particles).

The examination of different properties of plasma requires the use of a wide range of diagnostics with different amount and frequency of data collection. Critical plasma parameters are diagnosed simultaneously by several different techniques. This redundancy increases the reliability and reliability of the measurements obtained. In the ITER experiment, more than 50 different diagnostic systems classified as:

- magnetic (measurement of magnetic energy stored in plasma),

- neutron (neutron flow monitoring),

- optical (measuring density at the ends of the plasma),

- bolometric (measurement of energy transmitted by radiation),

- spectroscopic (radiation spectrum analysis),

- microwave (determination of plasma position),

- video (protection of components exposed to plasma).

One of the most important ITER Tokamak diagnostics, required already in the first phase of machine start-up, i.e. during hydrogen plasma production, is the diagnostics of runaway electrons emitted in the plasma. Monitoring of the "runaway electrons" is extremely important for the protection of the internal components of the machine, e.g. the first wall of the vacuum chamber. An increased number of released electrons can

lead to rapid wear and tear of the internal parts of the tokamak. Therefore, the monitoring and measurement of electrons emitted in plasma is one of the important requirements for all operational scenarios of the ITER Tokamak.

Diagnostics will be used to protect the machine and investigate the physical processes taking place in the plasma. HXRM (Hard X-Ray Monitor) diagnostics are used to measure the electrons released in the plasma. We are currently working on the I&C project of real-time electronic and information systems for HXRM diagnostics, according to the methodology developed in collaboration with scientists from ITER. In parallel, we are working on a prototype implementation of the I&C system. Prototyping includes evaluation of electronic components, data acquisition, first processing and analysis algorithms, as well as archiving and visualization of all necessary data.

Conclusions collected during prototyping are invaluable during system design and allowed to significantly improve the target system architecture. Completion of the system design is planned for the end of 2020. In accordance with the procedures adopted in the ITER Organization, the I&C system design will be evaluated by more than 30 experts from all over the world at the Final Design Review meeting at the beginning of 2021. Further work planned for 2021 includes construction of target electronics and software for HXRM diagnostics, conducting the first tests of the system and in the following years the installation of the system in tokamak.