Technologies are developing ever so fast, which triggers changes to happen in leaps and bounds across different sectors.

Consider communications. Surely the Scottish engineer's, Alexander Graham Bell's, invention - the phone, was one such big step. Another major leap was the launch of the first mobile phone by Motorola (1973) and the first smartphone by IBM (1992). No, there is no mistake - the first smartphone was not made by Apple, although the emergence of the iPhone could also be seen as yet another evolutionary stage in communications.

Why 4.0?

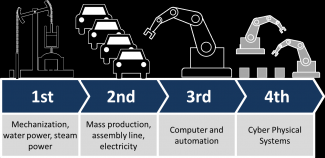

Before I get to the point, it is important to know why we are talking about the 4th revolution. Now, I can't really explain the ‘point zero’, except that it's a fad. However, digit 4 follows from the assumption that there have been three industrial revolutions so far:

The first industrial revolution is considered to have been industrialization. It began in the Anglo-Saxon countries in the 19th century and involved a shift from manual work to machinery-assisted work. Humans began to use machines such as the steam machine by the (again Scottish) inventor James Watt. Equipment powered by hydro energy was also introduced. Many cities, including Łódź, were born out of the first industrial revolution.

The second industrial revolution began in the early 1900s. The use of fuels and electrification paved the way for improved work organization and a new order with mass production and assembly lines. One important symbol of this period was the establishment of the Ford Motor Company in 1903. Also very inspiring is the story of the footwear manufacturing plant established at one of Poland's neighboring countries by Tomasz Bata (which is wonderfully described in the book Gottland).

As for the third industrial revolution, many of us were here to see it happen. With integrated circuits and computers, the way for further automation of industrial processes was wide open. Processes can now be controlled by computers and automation. Programming the entire industrial line has become a standard. It has also become possible to use industrial arms, automate the industrial process and establish global distribution channels.

Catch phrases of the Fourth Revolution

Automation has already become a standard and we are on the verge of another developmental leap. This time, advancement is driven by new communication and measurement technologies. Broadband connections, 5G networks, and smart sensors clear the way for a sudden emergence of countless new solutions.

Any revolution needs slogans and catchphrases. In this case, they are aplenty. Preachers of the 4th Industrial Revolution can't stop coming up with them:

IoT (Internet of Things) – not just computers, printers, modems. Most devices in the production plant will have communication protocols. This means unlimited possibilities for exchange of information between objects. The pressure transmitter may send a signal to the robotic arm which will, in turn, communicate with the position and temperature sensors and at the same time adjust the force of heated air flow.

Big Data - with communication so vast, unprecedented volumes of information are available. This gives us the opportunity to learn from the data and use it to optimize processes. The log of measurements may show us, for example, that a small correction of the position of the valve will increase the efficiency of the process by 1%. This will translate into hundreds of PLN per year. "Data is the new Oil" is experts' new mantra.

The volume of data available will double every year (my previous post is all about that). Its analysis will be more and more difficult for humans to carry out. Therefore, artificial intelligence will play a huge role in the fourth industrial revolution. On the basis of all historical data, an algorithm will draw conclusions for the future, which brings us to another watchword.

Predictive Maintenance - an algorithm that will be able to estimate future risks based on historical data. Bearings, compressor blades, and seals will be replaced in advance. Parts will not be replaced only after a failure has occurred or just before it occurs when the first signs of wear are already evident. Nor will it be replaced too often, as is currently the case with car maintenance. The replacement will be performed at a perfect moment when the part is still fully functional but the algorithm predicts its failure before the next inspection.

Digital Twin - each machine will have its virtual twin working concurrently. Imagine that when a car company sells a new car, it will run its virtual copy on its systems. A galore of measurements taken while the car is driven will be sent to the headquarters and processed by the virtual version of the car. If the algorithm returns notification of an imminent threat, the driver will receive a phone call - "At your current driving speed, your drive system is expected to fail within a thousand kilometers. Since you are travelling abroad, please continue to drive and do not accelerate above 140 km/g. When you have returned, please have the car serviced."

Additive Manufacturing - is nothing else but 3D printing but on a whole new level. Even today it is possible to print key machine parts such as gas turbine blades. In the future the machine will be able to repair itself by printing its parts. And whenever AI notifies of the possibility of process improvement with a modified component, the printer will certainly have it ready to be installed.

Autonomous robots - a higher level of automation. Machines will be small robots auto-controlling their performance and equipped with all the necessary senses via smart sensors. They will also be able to communicate with the server where parallel simulations will be done in the cloud.

Cloud computing - simulation of a running process. At present, many simulations of the air flowing through compressors are carried out. Such computations allow us to build better and more efficient constructions. We dream (and work towards that goal) that these simulations could be coupled with the real process and allow us to correct it in real time in a way similar to the digital twin example mentioned above.

A fascinating time of massive changes in the construction of everyday machines and equipment is coming. As soon as we get used to the catch phrases of the 4th Industrial Revolution, new ones related to the 5th and the 6th are bound to appear on the horizon. We may soon stop counting them and get used to the accelerating rate of progress.