Behind armor blunt trauma entails a risk of external and internal injuries that could cause bodily dysfunctions. Depending on their extent, they could lead to a serious disability eliminating the victim from their job or, in extreme cases, to death. Therefore, it is imperative that the performance of ballistic vests made from high-tenacity textile materials e.g. Twaron, Kevlar, Dyneema and Spectra, should be continually improved.

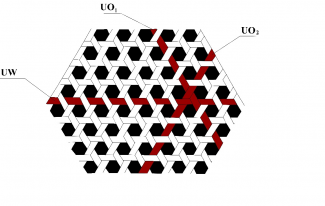

3-axial woven fabrics appear exceptionally promising textile structures for applications in soft panels of bulletproof vests. They are characterized by two systems of warp threads - UO1,UO2 where the UO1 system ofwarp threads is always over the UO2. The systems of warp threads are oriented towards the system of the weft threads UW at an angle of +60, -60°, respectively (Fig. 1).

Compared to two-axial woven fabrics currently used in bulletproof vests, three-axial wovens allow the impact energy to disperse radially across all the systems, which makes the area of the fabric that absorbs the kinetic energy of a projectile significantly larger than it is in two-axial fabrics, which, consequently, may result in minimization of physiologic effects of behind armor blunt trauma such as rib fracture, pulmonary contusions, and pneumothorax.