When you think of protective equipment for the respiratory system what comes to your mind is most probably the sight of a dentist or doctor performing a complex medical procedure. It is worth realizing that masks are used by medical personnel mostly to protect the patient against infection by the people performing medical procedures and not to protect the medical personnel directly. Nowadays, apart from medical professionals, many other occupational groups are exposed to airborne hazardous substances. These include people working in mines, concrete batching plants, compost plants, mills, lumber mills, paint shops, plants manufacturing fodder, spices, and many others.

Today, the topic of half-mask for protection of the respiratory system is also relevant for people exposed to smog, especially during physical activity - bike riding or running. That is why filtration half-masks are so widespread, and models available in the market offer protection in different filtration classes depending on how effective they are at filtering particles.

Disposable single-use half-masks are the most common, however, economic and environmental considerations compel researchers to look for solutions that will be suitable for multiple use and, at the same time, will retain all of their performance parameters.

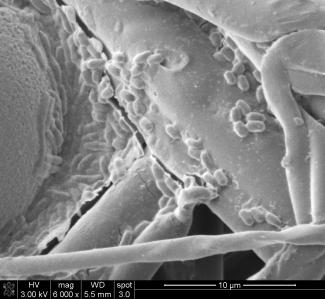

Scientists working in the Institute of Fermentation Technology and Microbiology in Lodz University of Technology and in the Department of Personal Protective Equipment in

the Central Institute for Labour Protection - National Research Institute have shown that within a short time of using a half-mask respirator, bacterial and fungal colonization occurs on its surface, especially under high humidity and high dustiness conditions (see the photo). Unfortunately, the filtering facepiece instead of protecting the user turns into a specific kind of 'a biological weapon'.

That is why there such a strong need for half-masks with biocidal properties to protect users against infectious, allergenic and toxic microbes.

For several years now, the Institute of Fermentation Technology and Microbiology has collaborated with the Department of Personal Protective Equipment in the Central Institute for Labour Protection - National Research Institute, and Adam Mickiewicz University in Poznań to develop bioactive filtration nonwovens for reusable respiratory protective equipment.

What is novel to the product is time-controlled release of minimal amounts of a biocidal agent (safe for humans) and, at the same time, retention of a broad spectrum of its biocidal efficacy.

Gemini surfactants are used as a biocidal agent as they exhibit much higher biocidal efficacy compared to other typical active substances. Functional biocidal structures have already been developed containing hexamethylene-1,6-bis(N,N-dimethyl-N-dodecylammonium bromide) (GS-12-6-12) deposited on halloysite nanocrystals, and their modification that additionally contained polyols that trigger their activity on contact with water vapour.

The developed nonwoven fabrics have shown high biocidal efficacy against control microorganisms, e.g. the reduction in the number of Escherichia coli bacteria after 24 contact hours was 98.35 - 99.99% (2-6 orders of magnitude on a logarithmic scale).

Ultimately, the nonwovens will be used in smart half-masks that will activate their antimicrobial activity depending on the conditions of use and user needs. Respiratory protective devices based on the developed nonwovens have already been made and their efficacy has been tested under conditions simulating the intended use conditions. Mass production of such protective half-masks will soon be launched.